Technology

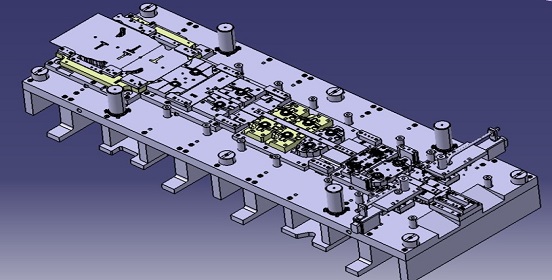

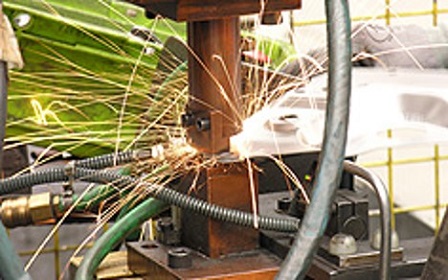

METALLIC STAMPING

Euro Estampaciones has a wide range of presses for progressive, transfer and conventional dies, from 1600 kN to 12500 kN.

Transfer presses from 6300 to 8000 kN are equipped with “link drive” transmission, and the 12500kN is a Servopress, all of them with programmable control, blank feeder, coil feeder and fast tool change.

The automatic presses for progressive dies are equipped with programmable control, fast tool change and are equipped with automatic band feeder for strip till 10mm thickness.

We have as well presses for second operations and assembling operations.